PCB SMTA Assembly

- 0

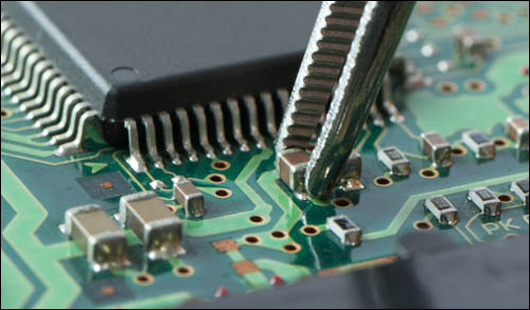

PCB SMTA (Printed Circuit Board Solderable Technology) assembly involves attaching components to a PCB using reflow soldering. This process is carried out at a temperature of up to 250oC. The melted solder fixes the components to the PCB and creates joints. The PCB then enters coolers where it solidifies the solder joints and forms a permanent bond between the SMT component and the PCB.

Reflow soldering is a part of pcb smt assembly

Reflow soldering is a part in the PCB SMT assembly process. This process is an effective way to solder surface mount components and fine-pitch leads. Hence, it is an ideal choice for mass-produced electronics. The process starts by applying solder paste onto the PCB. Then, the components are moved to the reflow soldering machine.

The process involves several individual processes that must be carried out in a specific order. First, the board must be preheated to a predetermined temperature. This is necessary to prevent components from being damaged by thermal shock. The temperature must be raised slowly so as to prevent a high rate of overheating the board. The reflow temperature should not exceed 250 degrees Celsius. The board must be monitored carefully to avoid any cracks or broken solder joints.

It allows for fine-pitch components to be mounted

Fine-pitch PCB assembly involves the use of a small spacing between adjacent SMD pads and solder balls, to achieve a close fit between components on the printed circuit board. The process requires high-speed, accurate functional mounting machines with fine-pitch capabilities.

Fine-pitch PCB assemblies are often used in high-density applications where circuit performance and precision are essential. PCBAs that use this technique should undergo Kelvin four-terminal sensing, a process that ensures circuit performance and precision. This testing method, which inspects 2,000 to 32,000 test points per second, can yield results with a 0.1-mO accuracy. This process also saves space and allows for more components to be mounted.

It reduces manufacturing costs

When you are looking for a PCB assembly company, you should look for a company that manufactures its components in bulk. This will allow the company to manufacture the components cheaper than what you would pay if you were doing it yourself. However, the quality will not be affected by this.

Another important factor to look for when choosing an assembly company is the level of automation. Automated equipment mounts components quickly and efficiently, which results in a high throughput and lower manufacturing costs. The faster the PCB assembly process is, the less labor it requires. Additionally, it allows engineers to use smaller components, which allows them to maximize the amount of PCB space available. As a result, manufacturers can reduce the size of their products and lower the weight of their products.

It allows for a smaller board design

The PCB SMT assembly process allows for fewer components and a smaller board design. The newest advancements in this process include increased speeds, improved soldering paste, and LED technology. Because of the pressure and expense, current PCB suppliers are being very competitive.

The PCB smt assembly process can be highly automated. It also allows for more compact design because components do not need to be mounted through holes. The resulting board design is also smaller because the components can be stacked closer together without causing a problem. Ultimately, this means a lighter and more robust design.